Liquid Acid Batteries: A Detailed Guide to their Composition,

These batteries rely on a chemical reaction between lead plates and sulfuric acid to produce electricity. This article delves into the details of liquid acid batteries, exploring their

Get Price

What you need to know about flow batteries

Flow batteries have a chemical battery foundation. In most flow batteries we find two liquified electrolytes (solutions) which flow and cycle through the area where the energy conversion

Get Price

What Are the Different Types of Home Energy Storage?

12 hours ago· 2. Lead-Acid Battery Storage Lead-acid batteries are one of the oldest home battery storage technologies. While heavier and less efficient than lithium-ion, they''re still used

Get Price

Lead Acid Battery

Construction of Lead Acid Battery The various parts of the lead acid battery are shown below. The container and the plates are the main part of the lead acid battery. The container stores

Get Price

6.10.1: Lead/acid batteries

The lead acid battery is the most used battery in the world. The most common is the SLI battery used for motor vehicles for engine S tarting, vehicle L ighting

Get Price

nanoFlowcell

In general, energy transfer within the flow cell runs between two platform-shaped poles (plus and minus) via an ionisable liquid, very similar to the time

Get Price

An Introduction To Flow Batteries

Traditional lead acid batteries can also be used in these applications but do not have the energy density, charging rate, or capacity that

Get Price

How Lead Acid Batteries Work

In this article, we''re going to learn about lead acid batteries and how they work. We''ll cover the basics of lead acid batteries, including their

Get Price

Soluble Lead Redox Flow Batteries: Status and Challenges

This is an exclusive review on soluble redox flow batteries which have proximity to conventional lead-acid batteries and are emerging technologies with all the benefits of lead

Get Price

Flow battery

Flow battery design can be further classified into full flow, semi-flow, and membraneless. The fundamental difference between conventional and flow batteries is that energy is stored in the

Get Price

Flow battery

OverviewHybridHistoryDesignEvaluationTraditional flow batteriesOrganicOther types

The hybrid flow battery (HFB) uses one or more electroactive components deposited as a solid layer. The major disadvantage is that this reduces decoupled energy and power. The cell contains one battery electrode and one fuel cell electrode. This type is limited in energy by the electrode surface area. HFBs include zinc–bromine, zinc–cerium, soluble lead–acid, and all-iron flow batteries. Weng et al

Get Price

What Are Liquid Flow Batteries And Their Advantages?

Flow batteries can be divided into all-vanadium flow batteries, lithium-ion flow batteries and lead-acid flow batteries according to the different

Get Price

What Are Liquid Flow Batteries And Their Advantages?

Flow batteries can be divided into all-vanadium flow batteries, lithium-ion flow batteries and lead-acid flow batteries according to the different electrode active materials.

Get Price

Flow Batteries: The Future of Energy Storage

Flow batteries are rechargeable batteries where energy is stored in liquid electrolytes that flow through a system of cells. Unlike traditional lithium-ion or lead-acid

Get Price

What you need to know about flow batteries

What is unique about a flow battery? Flow batteries have a chemical battery foundation. In most flow batteries we find two liquified electrolytes (solutions) which flow and cycle through the

Get Price

What is a Lead-Acid Battery? Construction, Operation,

This article provides an overview of the construction, working principles, and maintenance of lead-acid battery, commonly used in automobiles. It covers

Get Price

Liquid Acid Batteries: A Detailed Guide to their

These batteries rely on a chemical reaction between lead plates and sulfuric acid to produce electricity. This article delves into the details of liquid acid batteries,

Get Price

Flow Batteries: The Future of Energy Storage

Flow batteries are rechargeable batteries where energy is stored in liquid electrolytes that flow through a system of cells. Unlike traditional lithium

Get Price

nanoFlowcell

In general, energy transfer within the flow cell runs between two platform-shaped poles (plus and minus) via an ionisable liquid, very similar to the time-honoured lead-acid car battery.

Get Price

What is a Battery Electrolyte? Solid vs Liquid Electrolytes

Liquid electrolytes are the most common type found in batteries today. They consist of a solvent, usually an organic liquid, and a dissolved salt that provides the necessary ions for conduction.

Get Price

What is a Flow Battery? A Comprehensive Introduction to Liquid

What is a flow battery? A flow battery is a type of rechargeable battery that stores electrical energy in two electrolyte liquids in a separate tank. The liquid contained in the flow

Get Price

Lead Acid Battery: What''s Inside, Components, Construction, and

A lead-acid battery has three main parts: the negative electrode (anode) made of lead, the positive electrode (cathode) made of lead dioxide, and an electrolyte of aqueous

Get Price

5 Key Differences Between Flow Batteries and Lithium

The differences between flow batteries and lithium ion batteries are cost, longevity, power density, safety and space efficiency.

Get Price

Electrolytes in Battery : From Lithium Ion to Lead Acid

Electrolytes are essential components that enable ion flow between a battery''s electrodes, crucial for energy conversion and storage. From sulfuric acid in lead-acid batteries

Get Price

Technology Strategy Assessment

Redox flow batteries (RFBs) or flow batteries (FBs)—the two names are interchangeable in most cases—are an innovative technology that offers a bidirectional energy

Get Price

What is a Flow Battery? A Comprehensive

What is a flow battery? A flow battery is a type of rechargeable battery that stores electrical energy in two electrolyte liquids in a separate

Get Price

Soluble Lead Redox Flow Batteries: Status and

This is an exclusive review on soluble redox flow batteries which have proximity to conventional lead-acid batteries and are emerging

Get Price

[Compare Battery Electrolyte] Lithium vs. Lead-Acid

Compare electrolytes for different battery types. Find out which one offers better performance for lead-acid, NiCd, and lithium batteries.

Get Price

A novel flow battery—A lead acid battery based on an electrolyte

In this paper, we discuss the influence of state of charge, current density, electrolyte flow rate and temperature on the flow battery characteristics. The electrolyte in the

Get Price

New all-liquid iron flow battery for grid energy storage

A new iron-based aqueous flow battery shows promise for grid energy storage applications. A commonplace chemical used in water treatment facilities has been repurposed

Get Price

6 FAQs about [Liquid flow battery lead acid]

What are soluble lead redox flow batteries?

Soluble lead redox flow batteries are allied with conventional lead-acid batteries. They both have similar beneficial characteristics with low-cost, abundant raw materials with an added advantage of SLRFB, which can overcome the drawbacks of lead-acid batteries for large-scale energy storage applications.

What are the different types of flow batteries?

Flow battery design can be further classified into full flow, semi-flow, and membraneless. The fundamental difference between conventional and flow batteries is that energy is stored in the electrode material in conventional batteries, while in flow batteries it is stored in the electrolyte.

How do soluble redox flow batteries form a passive layer?

The formation of the passive layer in soluble redox flow batteries is allied with the passivation of PbO 2 in a positive plate of conventional lead acid batteries during discharge in sulphuric acid electrolyte.

What is a soluble lead (II) flow battery?

The soluble lead (II), lead–acid flow battery has been shown to give a good performance over a range of conditions including state of charge, current density, electrolyte flow rate and temperature.

Are flow batteries flammable?

Flow batteries use non-flammable liquid electrolytes, reducing the risk of fire or explosion—a critical advantage in high-capacity systems. Many flow batteries, such as vanadium-based systems, use materials that can be recycled, reducing their environmental impact.

How do flow batteries work?

Flow batteries operate based on the principles of oxidation and reduction (redox) reactions. Here’s a simplified breakdown of the process: Charging: During charging, electrical energy drives chemical reactions in the electrolyte, storing energy.

More related information

-

How big is the liquid flow battery in mobile base station equipment

How big is the liquid flow battery in mobile base station equipment

-

Qatar develops new liquid flow battery

Qatar develops new liquid flow battery

-

Long-lasting zinc-bromine non-fading liquid flow energy storage battery

Long-lasting zinc-bromine non-fading liquid flow energy storage battery

-

All-vanadium liquid flow battery industrial energy storage

All-vanadium liquid flow battery industrial energy storage

-

Liquid Flow Battery Lightning Protection for Iraqi Communication Base Stations

Liquid Flow Battery Lightning Protection for Iraqi Communication Base Stations

-

Panama energy liquid flow battery

Panama energy liquid flow battery

-

Qatar all-vanadium liquid flow energy storage battery

Qatar all-vanadium liquid flow energy storage battery

-

Nigerian lead acid battery bms

Nigerian lead acid battery bms

Commercial & Industrial Solar Storage Market Growth

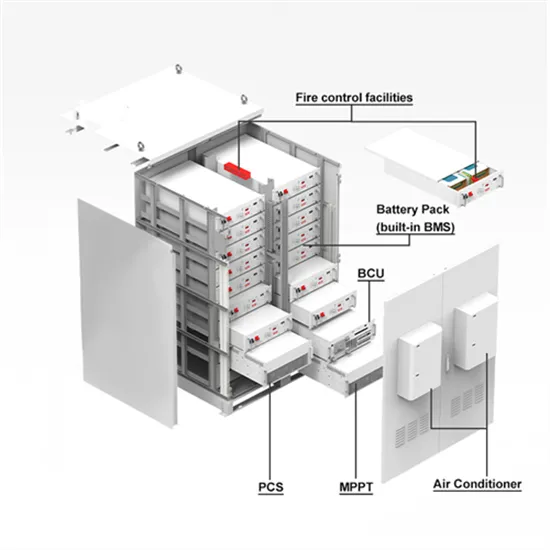

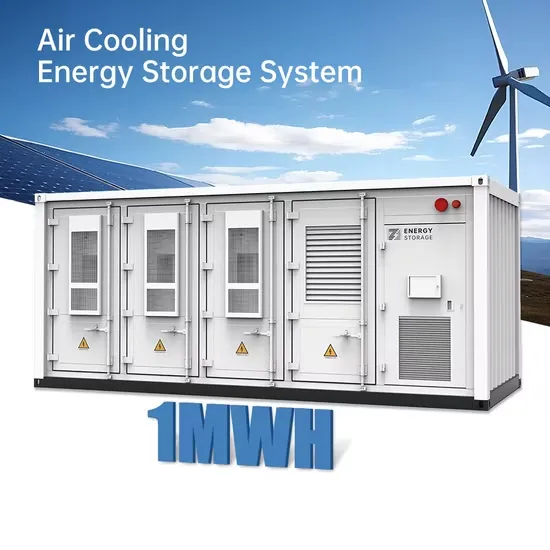

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

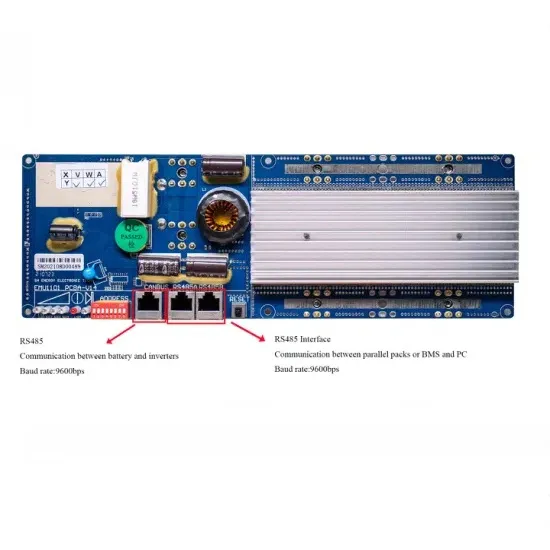

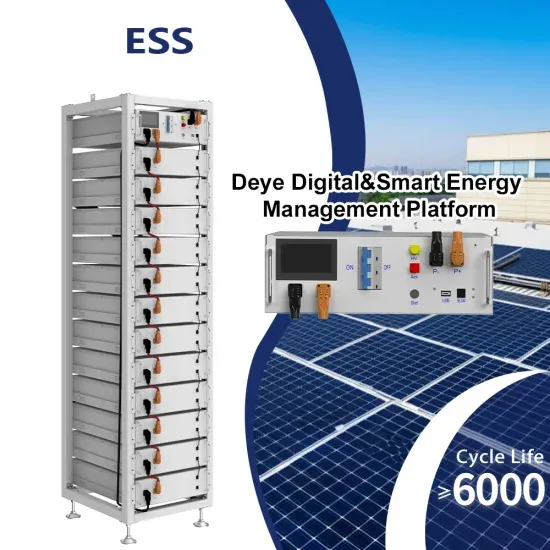

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.