Quality Management for Battery Production: A Quality

Methods of quality assurance in battery cell production have been demonstrated, for example, by Schnell and Reinhart, in which they proposed a

Get Price

A dialogue on advanced Lithium-ion battery inspection and analysis

Battery inspection solutions have become a critical aspect of the battery industry in recent years. As batteries are used in various applications, such as electric vehicles, energy

Get Price

Lithium-ion battery cells incoming inspection solution

As a professional battery pack assembly equipment and battery testing equipment supplier, WinAck can provide mature lithium-ion battery cell

Get Price

Battery Quality Inspection

Battery quality inspection of lithium ion batteries As manufacturers and regulators pivot towards vehicle electrification (1), lithium-ion batteries (LIBs) remain the most widely

Get Price

Battery & Energy Storage Testing | CSA Group

CSA Group provides battery & energy storage testing. We evaluate and certify to standards required to give battery and energy storage products access to

Get Price

Energy Storage Solutions Inspection Checklist and Template

Check the product''s storage capacity or battery life to ensure it meets the specified requirements. Inspect the product''s cooling system or ventilation to ensure it is free from obstructions or

Get Price

Battery Pack EOL Test: Ensure Safety & Performance

Explore the importance of the Battery Pack EOL Test in verifying battery safety, performance, and compliance during the final stage of lithium

Get Price

Lithium-Ion Battery Inspection System for EVs | SpringerLink

The Lithium-ion Battery Inspection System using ML and DL algorithms is a groundbreaking approach that addresses the pressing need for rigorous quality control and

Get Price

Active Thermography for Battery Weld Inspection

The cell and battery pack weld quality is critical as it affects the function and performance of the entire energy storage system. MoviTHERM BWI (Battery Weld Inspection) is an "out of the

Get Price

Battery FAT vs SAT Testing Explained | Factory vs Site

FAT and SAT act as a battery system''s "final exam" and "job interview"—one certifies product quality, the other proves real-world readiness. Understanding their roles helps prevent

Get Price

Quality Assurance – Electrios Consultants

Energy storage projects whether kilowatts or megawatts involve complex supply chains. We ensure high quality is maintained throughout the process from

Get Price

Energy Storage Solutions Inspection Checklist and

Check the product''s storage capacity or battery life to ensure it meets the specified requirements. Inspect the product''s cooling system or ventilation to

Get Price

Battery Energy Storage Systems (BESS) Quality

Apply robust Quality Control and QA testing for Battery Energy Storage Systems (BESS) to optimize performance, ensure safety, and prevent unpredictable

Get Price

Battery

Higher production speeds. Stricter quality requirements. More complex battery designs. These trends are shaping the future of battery manufacturing — and making it harder than ever to

Get Price

Battery Testing and Energy Storage Solutions

Comprehensive Battery Testing and Certification solutions for batteries and energy storage systems, ensuring products meet performance, reliability and

Get Price

Battery Energy Storage System Inspection and Testing

These Guidelines provide information on the Inspection and Testing procedures to be carried out by the eligible consumer at the end of the construction of a BESS System, in order to connect

Get Price

Battery FAT vs SAT Testing Explained | Factory vs

FAT and SAT act as a battery system''s "final exam" and "job interview"—one certifies product quality, the other proves real-world readiness. Understanding

Get Price

The BESS System: Construction, Commissioning, and O&M Guide

A comprehensive guide on the construction, commissioning, and operation & maintenance of industrial and commercial energy storage systems.

Get Price

Sinovoltaics Launches BESSential Quality Control

A global group that provides quality assurance for the battery energy storage system (BESS) and solar photovoltaic (PV) industries has

Get Price

BESS Quality Manufacturing and QC for Energy Storage Systems

Understand how Battery Energy Storage Systems (BESS) are made. Learn key steps, QC tests to ensure safe, efficient and reliable battery energy storage solutions.

Get Price

Quality Assurance – Electrios Consultants

Energy storage projects whether kilowatts or megawatts involve complex supply chains. We ensure high quality is maintained throughout the process from project design, manufacturing to

Get Price

Energy Storage Product Inspection Standards: What You Need to

Energy storage product inspection standards act as the ultimate quality control checklist, preventing your clean energy dreams from literally going up in smoke.

Get Price

Battery Energy Storage Systems (BESS) Quality Control and

Apply robust Quality Control and QA testing for Battery Energy Storage Systems (BESS) to optimize performance, ensure safety, and prevent unpredictable expensive issues.

Get Price

New York Battery Energy Storage System Guidebook for

The Battery Energy Storage System Guidebook (Guidebook) helps local government officials, and Authorities Having Jurisdiction (AHJs), understand and develop a battery energy storage

Get Price

Energy Storage Quality Control | Applus+ USA

Energy storage quality assurance and quality control (QA/QC) services ensure the reliability, safety, and long-term performance of battery energy storage systems (BESS).

Get Price

Quality Control and Testing for Battery Energy Storage Systems

CEA''s proactive and robust Quality Control and Testing program proactively identifies and resolves issues at every stage of battery energy storage system production – before they

Get Price

BATTERY FAT and SAT Major Testing Components & Procedures

In conclusion, Battery FAT (Factory Acceptance Testing) and SAT (Site Acceptance Testing) are vital processes in ensuring the quality and performance of battery

Get Price

A Comprehensive Approach to Battery Module and Pack Testing

This research article explores the key elements of battery module and pack testing, providing insights into industry-standard testing procedures and emerging testing methodologies.

Get Price

6 FAQs about [Energy storage battery pack quality inspection]

What is a standardized battery testing protocol?

Various organizations and regulatory bodies have established standardized testing protocols to ensure consistency and reliability across battery systems. International standards such as IEC 62660 (for automotive batteries) and UL 2580 (for stationary energy storage) provide guidelines for conducting comprehensive tests.

Why are battery testing protocols important?

With the growing reliance on batteries in electric vehicles, grid storage, and consumer electronics, robust testing protocols are essential for mitigating risks, improving efficiency, and meeting regulatory requirements.

What should be included in a battery test?

This should include at least: Verification of interconnected battery rack or string functionality. Auxiliary equipment testing, including standard operational lighting, emergency lighting, and HVAC or other thermal management system functionality.

How are batteries transforming energy storage?

The global transition toward renewable energy and electric mobility has placed batteries, especially lithium-ion battery modules and packs, at the forefront of energy storage technology. These battery systems are complex, consisting of interconnected cells that work together to store and deliver power efficiently.

How can AI improve battery testing?

AI-driven testing systems can analyze large datasets from battery testing, identifying patterns and predicting failure modes before they occur. Machine learning models can optimize testing protocols and provide insights into battery aging and degradation.

What are electrical tests for a battery?

Electrical tests evaluate the battery ‘s capacity, power output, energy efficiency, and response to electrical stress. Some of the key tests include: Capacity Testing: Measures the actual energy storage capacity of the battery, which is crucial for assessing its performance under load.

More related information

-

Energy Storage Battery Quality Inspection

Energy Storage Battery Quality Inspection

-

Home 5kwh energy storage battery pack

Home 5kwh energy storage battery pack

-

Internal structure of energy storage battery pack

Internal structure of energy storage battery pack

-

South Ossetia industrial energy storage lithium battery pack

South Ossetia industrial energy storage lithium battery pack

-

Malaysian quality energy storage battery company

Malaysian quality energy storage battery company

-

Swedish energy storage lithium battery quality merchant

Swedish energy storage lithium battery quality merchant

-

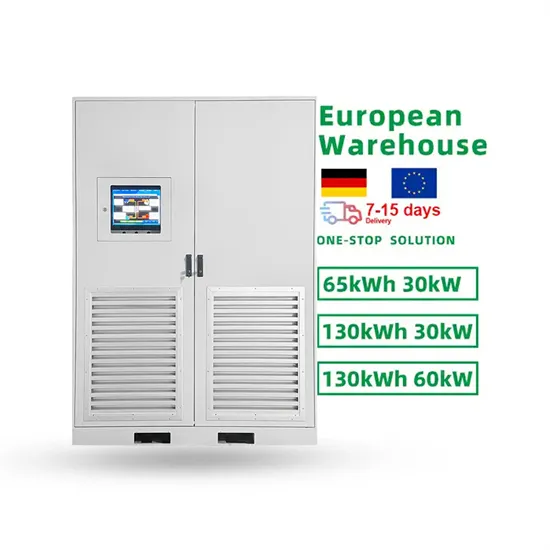

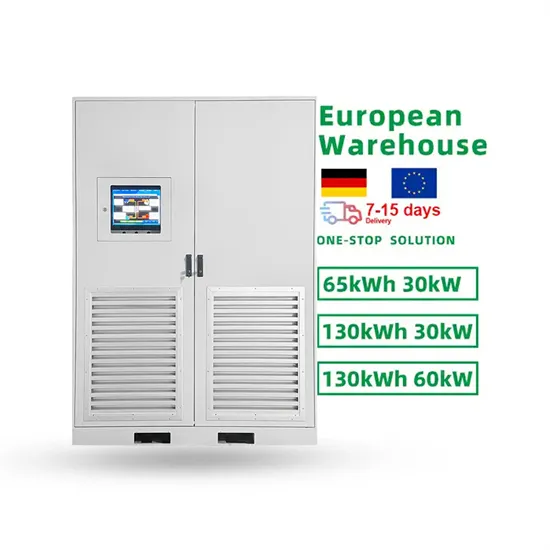

Energy storage cabinet pack battery

Energy storage cabinet pack battery

-

China s quality energy storage battery brand

China s quality energy storage battery brand

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.