Battery Manufacturing | Battery Design | Battery Assembly

We manufacture a variety of custom battery packs and power supplies made to customer specifications. Explore battery pack design and battery pack manufacturing at Ttek AI, a

Get Price

How to design battery packs, tutorial for Design Engineers

April 21, 2023 Engineering Guidelines for Designing Battery Packs Custom design and manufacture of state-of-the-art battery chargers, battery packs, UPS, and power supplies

Get Price

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get Price

Battery Pack Designer''s Guide: From Beginner to Pro [With

Battery pack design requires understanding both fundamental electrochemistry and application-specific engineering requirements. Custom battery pack applications have expanded

Get Price

Cylindrical Battery Pack Manufacturer

We design and manufacture custom cylindrical battery packs for industries globally including Lithium Ion, NiMH, Polymer and LiFePO4.

Get Price

Custom Battery Solutions Provider | Excell Battery

Excell Battery Company is an ISO 9001:2008 certified battery manufacturer specializing in custom battery packs. Can we help you with your

Get Price

Top 10: EV Battery Manufacturers

The automotive landscape is changing rapidly and with lead times and electric vehicle (EV) innovation being key factors in meeting sustainable

Get Price

The Handbook of Lithium-Ion

The Handbook of Lithium-Ion Battery Pack Design This page intentionally left blank The Handbook of Lithium-Ion Battery Pack Design Chemistry, Components, Types and

Get Price

High-Quality Battery Design | Excell Battery

Excell Battery will work with you to understand your battery needs and help guide you through the battery design process. We make sure our customers

Get Price

FEATURE: Battery Design – the shape of things to come

The past decade, the electric vehicle industry has witnessed advancements in battery pack design influenced by innovative design trends.

Get Price

Battery Design Explained: From Prototyping to Certification

Learn how to design efficient, compliant battery packs for drones, robotics, medical devices, and e-mobility. Explore chemistries, BMS, certification, performance

Get Price

Designing a Battery Pack?

When you think about designing a battery pack for electric vehicles you think at cell, module, BMS and pack level. However, you need to also rapidly think in

Get Price

Designing a Battery Pack?

When you think about designing a battery pack for electric vehicles you think at cell, module, BMS and pack level. However, you need to also rapidly think in terms of: electrical, thermal,

Get Price

Battery Pack Manufacturing Process

In this post, you''ll learn the entire battery pack manufacturing process. We''ll cover cell selection, module assembly, safety testing, and future innovations. Whether you''re a

Get Price

Expert Battery Pack Engineering & Manufacturing for High

Our team specializes in custom battery pack specifications, actively participates in production processes, and is dedicated to supporting your engineers in developing the ideal battery pack

Get Price

Top 12 Lithium Ion Battery Manufacturers in the UK

Discover the top 12 Lithium Ion battery manufacturers in the UK. Choose from industry-leading companies for quality products and cutting-edge technology.

Get Price

High-Quality Battery Design | Excell Battery

Excell Battery will work with you to understand your battery needs and help guide you through the battery design process. We make sure our customers understand safety requirements and

Get Price

Custom Battery Pack Manufacturer (OEM)

Custom Battery Pack & Charger Manufacturer For over 30 years, the Power Products team has been helping companies across a variety of industries,

Get Price

Battery Pack Manufacturing Process

In this post, you''ll learn the entire battery pack manufacturing process. We''ll cover cell selection, module assembly, safety testing, and

Get Price

EV Lithium Battery PACK Design Process from Manufacturers

At Bonnen Battery, our engineering team follows a systematic approach to battery pack design, ensuring optimal performance and safety for various EV applications. This blog

Get Price

Custom Battery Pack Assembler | North America

Experience premier custom battery pack assembler in North America with National Power Corporation. We provide top-quality and reliable

Get Price

About Us

We craft high-performance drone lithium battery packs that soar alongside innovation, and AGV and robotic battery packs that fuel the future of automation. We even power industrial

Get Price

Expert Battery Pack Engineering & Manufacturing for

Our team specializes in custom battery pack specifications, actively participates in production processes, and is dedicated to supporting your engineers in

Get Price

Custom Battery Packs Manufacturer & Design

Whether you call them custom battery packs, custom batteries, bespoke battery packs, bespoke batteries or just battery packs, Euro Energy are a leading UK

Get Price

Custom Battery Pack Manufacturer – Trusted Power Solutions

From lithium-ion to NiCd and alkaline, we design and build battery packs tailored to your needs. Get reliable, high-performance power for any application.

Get Price

Design approach for electric vehicle battery packs based on

This work proposes a multi-domain modelling methodology to support the design of new battery packs for automotive applications. The methodology allows electro-thermal

Get Price

Custom Battery Pack Designer & Engineer Solutions

Many years of combined expertise in engineering and manufacturing enable us to provide well designed, cost effective solutions that solve the extreme challenges OEM''s are faced with.

Get Price

6 FAQs about [Pack battery manufacturer design]

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

How do you design a custom lithium battery pack?

This blog post outlines the comprehensive design process we follow when developing custom lithium battery packs for our clients. The first and foundational step in battery pack design is a thorough analysis of requirements and specification definition. This initial phase sets the direction for the entire design process.

Is a custom battery pack better than a lithium-ion battery pack?

In some instances, a custom NiMH battery pack or custom alkaline battery pack may perform better than a lithium-ion battery pack, while keeping your costs lower. When involving our team of engineers early on in the design process, we can help assist you in choosing the proper custom battery solutions for your needs.

How to design a battery pack?

As a battery pack designer it is important to understand the cell in detail so that you can interface with it optimally. It is interesting to look at the Function of the Cell Can or Enclosure and to think about the relationship between the Mechanical, Electrical and Thermal design.

How to design a battery pack for electric vehicles?

When you think about designing a battery pack for electric vehicles you think at cell, module, BMS and pack level. However, you need to also rapidly think in terms of: electrical, thermal, mechanical, control and safety. Looking at the problem from different angles will help to ensure you don’t miss a critical element.

Why do you need a custom battery pack?

Customization ensures optimal performance, safety, and efficiency for various applications, including electric vehicles (EVs), consumer electronics, and energy storage systems. 1. Customizing Battery Packs for Specific Requirements

More related information

-

Swiss 26650 lithium battery pack manufacturer

Swiss 26650 lithium battery pack manufacturer

-

Fiji lithium battery pack manufacturer

Fiji lithium battery pack manufacturer

-

El Salvador lithium battery pack source manufacturer

El Salvador lithium battery pack source manufacturer

-

Monaco pack lithium battery custom manufacturer

Monaco pack lithium battery custom manufacturer

-

Lithium battery pack design and assembly

Lithium battery pack design and assembly

-

Saint Kitts and Nevis lithium battery pack manufacturer

Saint Kitts and Nevis lithium battery pack manufacturer

-

Yaounde lithium battery pack source manufacturer

Yaounde lithium battery pack source manufacturer

-

Which lithium battery pack manufacturer in Myanmar is the best

Which lithium battery pack manufacturer in Myanmar is the best

Commercial & Industrial Solar Storage Market Growth

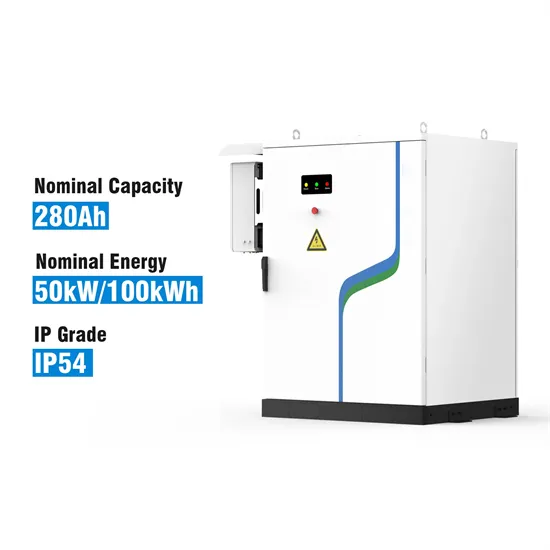

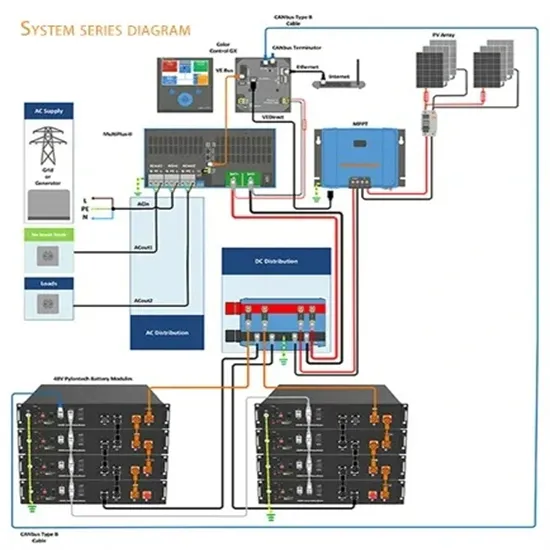

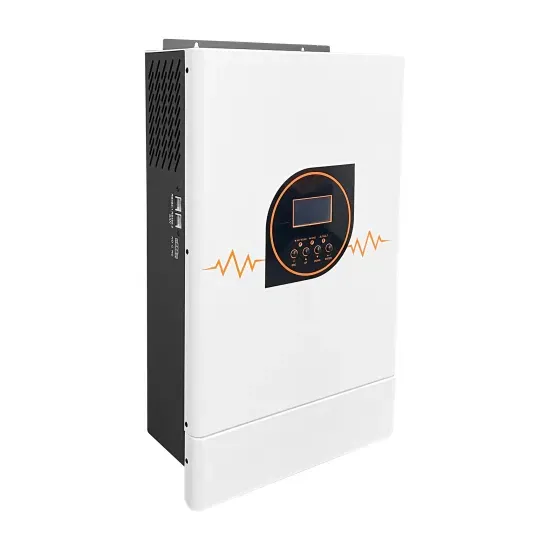

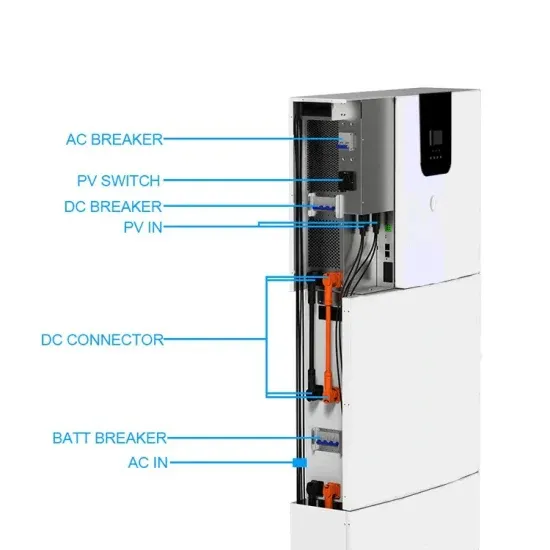

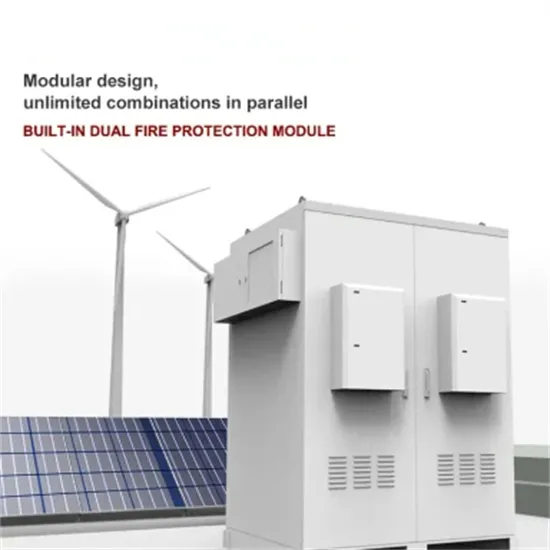

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.