Cell Balancing Techniques in Lithium Battery BMS:

Explore the key differences between passive and active cell balancing techniques in lithium battery BMS systems. Learn how each method

Get Price

The Ultimate Guide to Active Cell Balancing BMS

An intelligent system called a BMS with active cell balancing is made to keep an eye on, control, and maximize the performance of battery cells, particularly those found in

Get Price

Comparison of Battery balancing methods: Active cell balancing

To address this issue and improve the lifetime of battery packs, cell balancing methods have been developed. These methods can be broadly categorized into four types:

Get Price

Active Balancing: How It Works

Among the three types of active balancers, the bidirectional buck-boost active balancer is the simplest and most reliable. Table 1 compares all three active balancing methods.

Get Price

Active vs. Passive Balancing: A Guide to LiFePO4 Cells

Balancing the cells is crucial when it comes to maintaining the performance and longevity of LiFePO4 battery packs. But did you know there

Get Price

Effective Cell Balancing in BMS: Maximizing Battery Health | NAZ

Explore the importance of cell balancing in BMS for lithium batteries, covering active and passive methods to enhance battery efficiency and safety.

Get Price

A Deeper Look into Active Balancing on BMS

Simplicity and efficiency—even if not the shared pursuit of all designers—are the goals for most. Following the principle that simplicity wins, this

Get Price

Battery Balancing: A Crucial Function of Battery Management

In the world of rechargeable batteries, one function of the Battery Management System (BMS) stands out as essential for improving performance and longevity, especially for the batteries

Get Price

Comparison of Battery balancing methods: Active cell

To address this issue and improve the lifetime of battery packs, cell balancing methods have been developed. These methods can be broadly

Get Price

Active and Passive Battery Pack Balancing Methods

There are a variety of ways to keeps a battery pack properly balanced. This article introduces the concept of active and passive cell

Get Price

A critical review of battery cell balancing techniques, optimal

Considering the significant contribution of cell balancing in battery management system (BMS), this study provides a detailed overview of cell balancing methods and

Get Price

Active balancing: How it works and what are its advantages

As an alternative to passive balancing, active balancing uses power conversion to redistribute charge among the cells in a battery pack. This enables a higher balancing current,

Get Price

What Is Active Cell Balancing, Types, Advantages,

This article will be on what is active cell balancing, the types of active cell balancing, its working, its advantages, disadvantages, and its application of

Get Price

What is BMS Battery Management System?

A BMS battery management system refers to an electronic system responsible for overseeing the operations of a rechargeable battery.

Get Price

Active cell balancing to maximise the potential of battery storage

Active cell balancing can mitigate many of the issues that arise in battery storage for applications including renewable energy integration, but careful analysis and consideration

Get Price

Active Battery Cell Balancing | Analog Devices

Active cell balancing is a more complex balancing technique that redistributes charge between battery cells during the charge and discharge cycles, thereby increasing

Get Price

Active balancing vs. Passive balancing in Battery BMS

Active balancing and passive balancing are two methods used in battery management systems (BMS) to ensure that all cells within a battery

Get Price

Battery Management Systems (BMS)

A Battery Management System (BMS) is an electronic system that manages and monitors rechargeable batteries, ensuring their safe and eficient operation. It consists of hardware and

Get Price

1S, 2S, 3S, 4S BMS Circuit Diagram for Li-ion Batteries

In this guide, we will dive deep into BMS circuit diagram for 1S, 2S, 3S, and 4S Li-ion battery configurations, providing detailed explanations of its components and functionality.

Get Price

Battery Balancing: A Crucial Function of Battery

Battery Balancing: A Crucial Function of Battery Management Systems In the world of rechargeable batteries, one function of the Battery Management System (BMS) stands out as

Get Price

Active balancing vs. Passive balancing in Battery BMS

What is the main difference between active and passive balancing? Active balancing redistributes energy between cells, while passive

Get Price

Active balancing vs. Passive balancing in Battery BMS

What is the main difference between active and passive balancing? Active balancing redistributes energy between cells, while passive balancing dissipates excess

Get Price

A novel active cell balancing topology for serially connected Li-ion

In a Battery Management System (BMS), cell balancing plays an essential role in mitigating inconsistencies of state of charge (SoCs) in lithium-ion (Li-ion) cells in a battery

Get Price

Active cell balancing for electric vehicle battery

Cell balancing enhances battery safety and extends battery life. This paper discusses about different active balancing method to increase the life

Get Price

Cell Balancing Techniques in Lithium Battery BMS: Passive vs. Active

Explore the key differences between passive and active cell balancing techniques in lithium battery BMS systems. Learn how each method impacts performance, safety, and

Get Price

How Does A BMS Balance A Lithium Battery?

Usually, a BMS will balance a battery by burning off the excess energy that is found in the highest cell group. More sophisticated and more

Get Price

More related information

-

Energy Storage Battery Management Active Balancing

Energy Storage Battery Management Active Balancing

-

24 strings 8A lithium battery pack active balancing module

24 strings 8A lithium battery pack active balancing module

-

Automatic balancing BMS battery management system

Automatic balancing BMS battery management system

-

The difference between ASEAN lithium battery and lithium iron phosphate battery BMS

The difference between ASEAN lithium battery and lithium iron phosphate battery BMS

-

Battery BMS main functions

Battery BMS main functions

-

Bangladesh new energy lithium battery BMS structure

Bangladesh new energy lithium battery BMS structure

-

Battery Management System BMS Control Price

Battery Management System BMS Control Price

-

How many M battery BMS

How many M battery BMS

Commercial & Industrial Solar Storage Market Growth

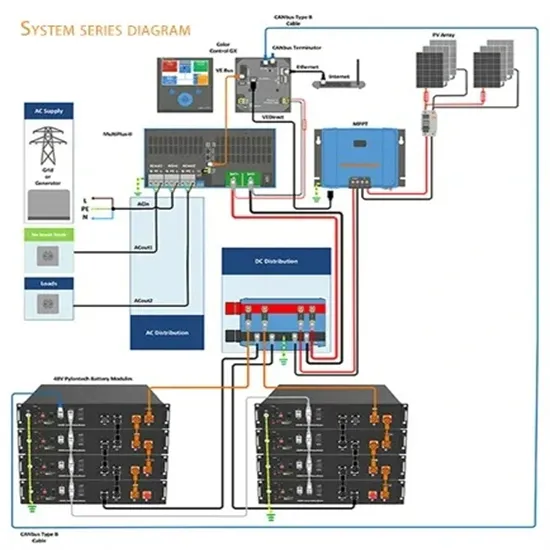

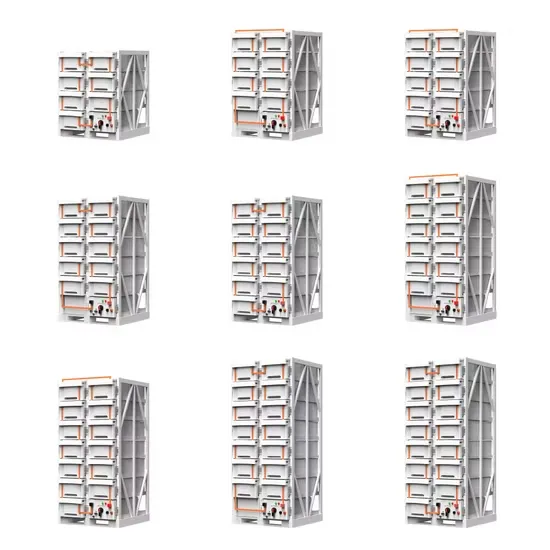

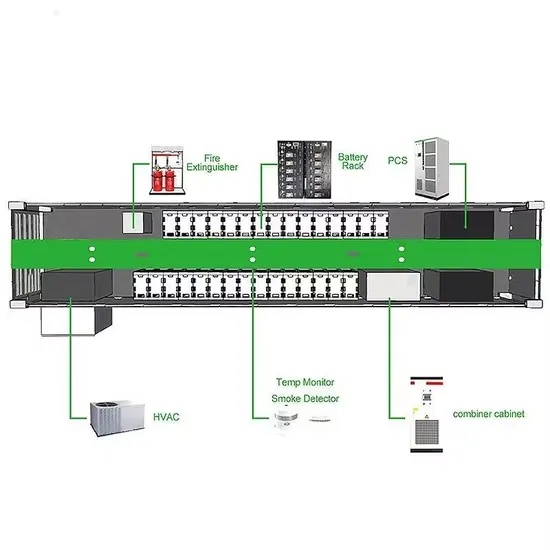

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

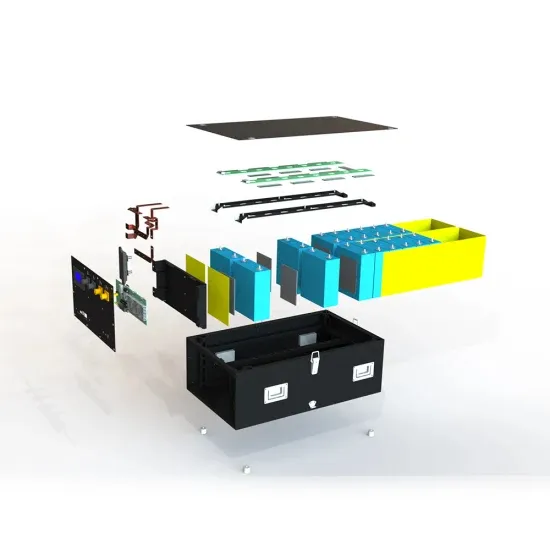

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.