Pre-Charging an inverter

The solution to connecting large capacitive loads is to pre-charge using a controlled current. This should only need to be done on first connection, or if the inverter is left disconnected for a long

Get Price

Active Front End (AFE)

DC bus pre-charging techniques, the grid-connected operation of power converters requires its DC bus voltage to be higher than the rectified

Get Price

ALLWEI 300W Power Inverter DC 12V to 110V AC, Compact Car

Buy ALLWEI 300W Power Inverter DC 12V to 110V AC, Compact Car Plug Adapter Outlet with 65W PD USB-C &18W USB-A Fast Charging, Cigarette Lighter Adapter Car

Get Price

Battery Charging

Charging will only start when the inverter is initially off and goes through the precharge sequence. When you plug in your AC mains, the inverter will power

Get Price

Precharing of VFDs on a common dc-link | Eng-Tips

Some inverter manufacturers have on-board pre-charging circuits IGBT switches or Thyristors and resistors for ac and/or dc connection - Siemens, Alstom, for example, but could

Get Price

Charging Battery While Connected To Inverter: The

Power source options How to connect the charging system Following the outlined method below, you can ensure uninterrupted power by charging your battery

Get Price

Pre-charging inverter capacitors?

I''ve seen videos that say you need to pre-charge the inverter capacitors using a resistor when starting up a system that has Lithium ion batteries to prevent a rush of power. I

Get Price

How to pre-charge an inverter easily

In this mini-article, we will explain why you need to pre-charge some inverters, when it is required and how to do it. We''ll keep things quick and simple so you can get your inverter up and

Get Price

How to calculate precharging resistors and

I am searching some concrete document on how to calculate the precharging resistor installed in inverter which is used for precharging of DC link and AC

Get Price

Precharge Resistor: Essential Guide for Circuit

In electric vehicles (EVs), the high-voltage battery systems contain large capacitor banks within the inverter and other power electronic

Get Price

Inverter Pre-Charge Circuit Inrush Current

Pre-Charge Circuits Prevent Damage to Inverters Severe damage can occur to inverters when the inrush current is too great for the inverter. Pre-charge circuits protect the inverters by

Get Price

Inverter Pre-charge circuit

The pre-charge circuit I''d like to include before installing the new inverter will use a light bulb as suggested by many. I''m planning to place it permanently wired into the system,

Get Price

Precharge with AC input?

To understand how it works, turn off the inverter, disconnect the battery, put a voltmeter on the DC bolts of the inverter, turn on AC IN and wait a minute or two. If you

Get Price

PRE charger modules | pr-electronics

Products - Charger modules Since 2009 PRE is a well-known Power Module supplier for OEM companies. Our customers provide DC Fast Charging solutions all over the world. PRE is your

Get Price

Inverter Pre-Charge Circuit Inrush Current

Pre-Charge Circuits Prevent Damage to Inverters Severe damage can occur to inverters when the inrush current is too great for the inverter. Pre-charge

Get Price

Voltage Source Inverter with Pre-Charge

A stiff three-phase voltage source with line inductance is connected to the AC-side of 2-level IGBT con-verter. This model extends the "Voltage Source Inverter" demo model by including pre

Get Price

How to Build & Wire an Inverter Pre-Charge Circuit

In this video, I walk you through the process of building and wiring an inverter pre-charge circuit to prevent sparks and inrush current when

Get Price

Renogy Solar 2000w pure sine wave inverter setup & pre-charge

I purchased a 2000 watt Renogy 12v DC to 110 volt AC pure sine wave power inverter. Amazon Affiliate link: https://amzn.to/3kzCuJ5 This video shows the unboxing, connection to a liIon battery pack

Get Price

Understanding How an Inverter Charger Charges

It regulates the voltage and frequency of the AC power, ensuring compatibility with standard electrical devices and appliances. B. Charger The

Get Price

Precharing of VFDs on a common dc-link | Eng-Tips

Dear colleagues, I am doing some brainstorming on how to complete a VFD-system with several large inverters connected to a common dc-link and with one rectifier to supply the

Get Price

DC bus pre-charging techniques

This application note presents a technique for pre-charging the DC bus of a grid-tie inverter from the AC side. This technique is commonly used in imperix systems.

Get Price

DC Pre-Charge Units for PV & Battery Inverters

PV Inverter Pre-Charge Requirements In most PV applications, pre-charge of the Inverter DC bus capacitance is not required due to the I-V

Get Price

Pre-Charge Resistor

The time taken to pre-charge the capacitors in the HV system will depend on the resistance in the total circuit, the voltage of the battery pack and the capacitance in the

Get Price

Li-Ion BMS

When initially connecting a battery to a load with capacitive input, there is an inrush of current as the load capacitance is charged up to the battery voltage.

Get Price

How to Build & Wire an Inverter Pre-Charge Circuit

In this video, I walk you through the process of building and wiring an inverter pre-charge circuit to prevent sparks and inrush current when connecting an inverter to a battery bank.

Get Price

Why Pre-Charge Circuits are Necessary in High-Voltage

Pre-charge circuits are often used in electric vehicles (EVs) such as battery management systems, on-board chargers, and in industrial applications such as power supplies and power

Get Price

DC bus pre-charging techniques

Pre-charge circuits are often used in electric vehicles (EVs) such as battery management systems, on-board chargers, and in industrial applications such as power supplies and power

Get Price

6 FAQs about [AC inverter pre-charging]

How does a pre-charge circuit protect the inverter?

Pre-charge circuits protect the inverters by controlling the initial power surge. PTC thermistors can help a pre-charge circuit protect the inverter. Inrush current occurs when the maximum instantaneous input current flows through a system when the electrical power is switched on.

Do I need to pre-charge my inverter?

All of our large inverter and inverter/charger kits include the required resistor to allow you to safely pre-charge it. If you have a lithium battery bank, it’s really important to pre-charge your inverter (2000W+) to protect your BMS. Nevertheless, pre-charging is still necessary if you have AGM batteries.

Can a grid-tie inverter be pre-charged from the AC side?

This application note presents a technique for pre-charging the DC bus of a grid-tie inverter from the AC side. This technique is commonly used in imperix systems. Proper solutions for discharging the power converter is also addressed. Why pre-charging an inverter’s DC-bus?

How do I use an AC pre-charge circuit?

One way of implementing that AC pre-charge circuit is by using imperix’s handy Grid connection panel. It includes the three current-limiting resistors and the two relays (controllable from a B-Box controller), as well as an additional circuit breaker. When the converter is not switching and that its DC bus is not charged, all contactors are open.

Why do inverters pre-charge a DC-BUS?

Why pre-charging an inverter’s DC-bus? Nowadays, Voltage Source Converter (VSCs) are widely used in grid-tied applications. They indeed offer several benefits over Current Source Converters (CSCs), such as reduced filtering requirements, superior efficiency and easier use in weak grid conditions.

How to charge a DC inverter?

Pre-charging an inverter is simple. You just need to connect a suitable resistor between the DC load and inverter for a few seconds. Then, remove the resistor and connect the DC load to the inverter. The following method breaks this down, step by step. Connect the inverter to your negative and positive busbars.

More related information

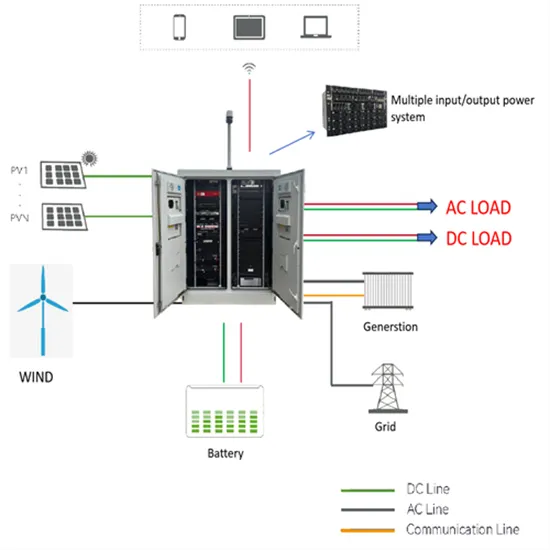

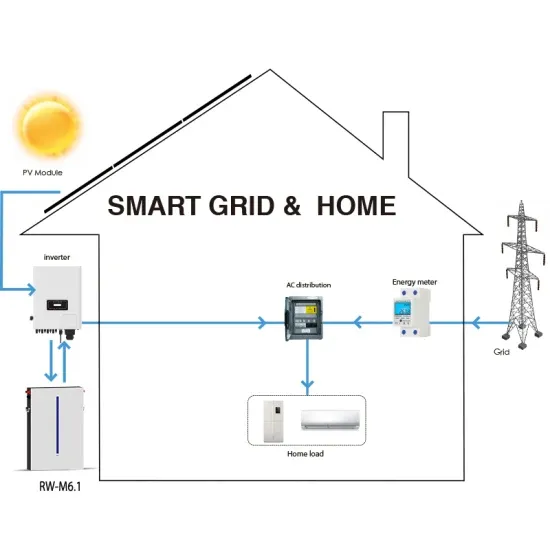

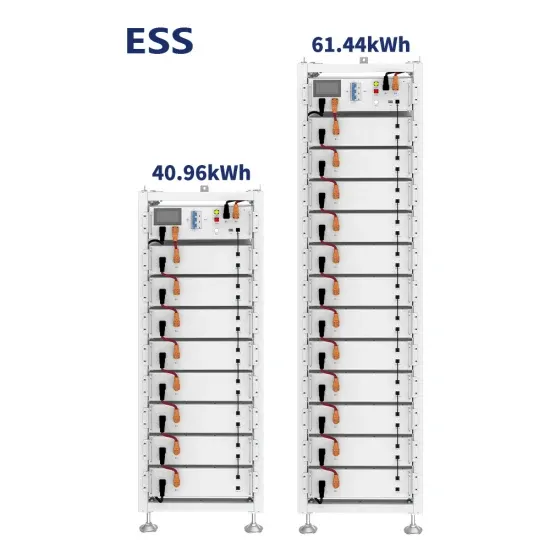

Commercial & Industrial Solar Storage Market Growth

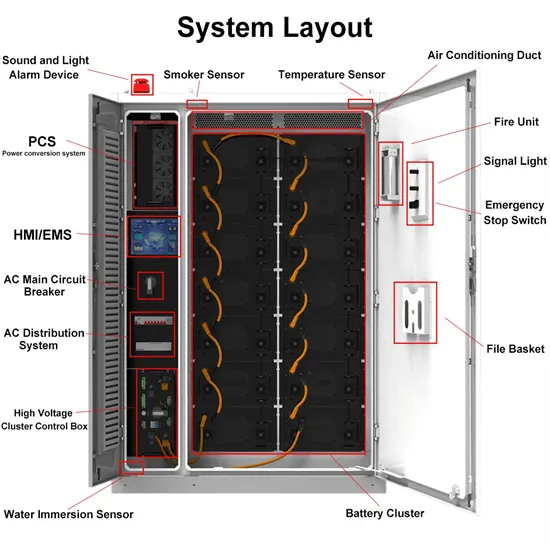

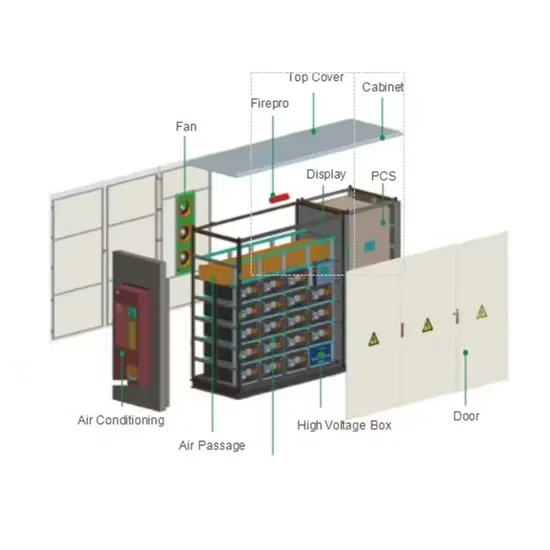

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.

Which brand of AC inverter is good

Which brand of AC inverter is good

Is it normal for the inverter to output 246V AC voltage

Is it normal for the inverter to output 246V AC voltage

380v DC to AC inverter

380v DC to AC inverter

Inverter AC 1 1 times output

Inverter AC 1 1 times output

AC side low voltage inverter protection

AC side low voltage inverter protection

How big an inverter does an 850w AC motor need

How big an inverter does an 850w AC motor need

Inverter converts AC to DC

Inverter converts AC to DC