What waste does a solar panel factory produce?

The production of solar panels leads to waste that includes hazardous materials, such as cadmium and lead, which can pose serious

Get Price

Large Pharmaceutical Manufacturing Factory royalty-free images

a large pharmaceutical manufacturing factory, spread in 14,000 sq metres upon 75% of the space of the plot, in a plot of ratio 2:1, building height of 15 metres, constructed with blue and white

Get Price

Solar Panel Manufacturing Cost: A Complete Factory Breakdown

Do you want to start a solar panel manufacturing factory and you need an in-depth solar panel manufacturing plant cost breakdown? If yes, then you are at the right place. In this

Get Price

Powering Manufacturing Plants with Solar:

Discover how engineering innovation powers manufacturing with solar energy, reducing costs, boosting efficiency, and leading sustainability efforts.

Get Price

Solar Manufacturing—Industrial Water Options

Solar PVs manufacturing facilities produce industrial wastewater streams with complex chemistries, which must be managed for reuse, discharge, or disposal. Constituents

Get Price

Solarix acquires Forest Facility

Solarix, a solar panel manufacturer announced that it acquired Forest facility in a move that will generate 104 new green energy jobs.

Get Price

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

Get Price

So I''ve heard of factories installing solar on their roofs... are there

My formulations and packaging plant could have easily run on solar + gas. We had no expensive heating or cooling processes, and what we did have was handled by a gas steam boiler.

Get Price

SABIC

The deal will see Iberdrola, one of the world''s biggest electricity utility companies, invest almost €70m to construct a 100MW solar PV facility with 263,000 panels, on land owned by SABIC,

Get Price

Powering Manufacturing Plants with Solar: Engineering the

Discover how engineering innovation powers manufacturing with solar energy, reducing costs, boosting efficiency, and leading sustainability efforts.

Get Price

Solar Power Plant: Types, Benefits, Price, Subsidy | Amplus

The solar power plant model is becoming increasingly popular for generating electricity without producing carbon emissions and causing environmental harm. As more and more people

Get Price

Types of Solar Panels Best for Industrial Use

Are you wondering what type solar panels are best suitable for your industrial plant? Learn about solar panels and how Coldwell Solar can help.

Get Price

What Chemicals Are Used to Make Solar Panels?

Solar panels use a variety of chemicals during the manufacturing process, from silicon processing to panel encapsulation. Cadmium telluride

Get Price

So I''ve heard of factories installing solar on their roofs... are there

My formulations and packaging plant could have easily run on solar + gas. We had no expensive heating or cooling processes, and what we did have was handled by a gas

Get Price

How To Start Solar Panel Manufacturing Business

For complete setup of solar panel manufacturing plant, it requires many components like a solar panel, DC distribution box, battery, panel stand, wire, tracking structures, etc. Solar

Get Price

How the Solar Panel Manufacturing Process Is Going

Solar panels and other electronic devices contain a number of harmful chemicals that are not easy to dispose of. Over the last few years, solar manufacturers

Get Price

Key Chemicals for Solar Panel Manufacturing and

Chemical suppliers can capitalize on this by offering specialized "quantum-grade" lines with guaranteed ultra-purity. Over time, we may

Get Price

How Solar Panels Are Made In Factory

We will discuss the process how solar panels are made in the industries and how sunlight energy is converted into electrical energy.

Get Price

Ideal Locations for Industrial Solar Panels | Coldwell

Are you planning to install industrial solar panels for your business? Read on to learn about the ideal locations for the best performance.

Get Price

How Solar Power Can Be Used in the Chemical Industry

Solar power can augment power for both to operate continuously within a limited range of operations. According to Manu Karan, Vice President of CleanMax, solar power can

Get Price

What waste does a solar panel factory produce? | NenPower

The production of solar panels leads to waste that includes hazardous materials, such as cadmium and lead, which can pose serious environmental and health risks if not

Get Price

Chemical Plant Fundamentals Explained

Definition: A chemical plant is a facility where chemical processes are carried out on an industrial scale to produce a variety of chemical

Get Price

Key Chemicals for Solar Panel Manufacturing and Thermal

Chemical suppliers can capitalize on this by offering specialized "quantum-grade" lines with guaranteed ultra-purity. Over time, we may witness joint ventures where quantum

Get Price

How the Solar Panel Manufacturing Process Is Going Green

Solar panels and other electronic devices contain a number of harmful chemicals that are not easy to dispose of. Over the last few years, solar manufacturers have made steps to reduce or

Get Price

What Chemicals Are Used to Make Solar Panels?

Solar panels use various chemicals during manufacturing, from silicon processing to encapsulation. Discover what chemicals are used to make solar panels.

Get Price

Solar energy

Solar energy is the radiant energy from the Sun ''s light and heat, which can be harnessed using a range of technologies such as solar electricity, solar

Get Price

Solar Power Plant Construction and Working: A

Working of a Solar Power Plant 1.Solar Energy Absorption In a PV solar power plant, solar panels made of photovoltaic cells absorb sunlight.

Get Price

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on

Get Price

6 FAQs about [Is a solar panel factory a chemical plant ]

Is solar power a good source of energy for chemical plants?

Solar power can augment power for both to operate continuously within a limited range of operations. According to Manu Karan, Vice President of CleanMax, solar power can be a very effective supplementary source of energy for chemical plants.

How do manufacturing plants benefit from solar energy?

Manufacturing plants benefit from technologies designed to meet their specific energy demands: Concentrated Solar Power (CSP): Engineered for high-temperature industrial applications like chemical processing, CSP systems provide a sustainable alternative to traditional heating methods.

How are solar panels made?

The making of solar panels needs many chemicals. This includes silicon, cadmium, and copper. It also uses hydrochloric acid and organic solvents. Each of these plays a big part in different steps of making the panels. They help with the raw materials, creating the cells, and putting the parts of the panel together.

How does solar manufacturing work?

How Does Solar Work? Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems.

Is solar power the future of manufacturing?

As manufacturing plants look to reduce costs and minimize their environmental footprint, solar energy emerges as a powerful solution. Solar power doesn’t just replace traditional energy sources—it redefines the way factories operate, combining advanced engineering with environmental responsibility to create smarter, greener industrial processes.

How does solar energy impact the chemical industry?

This progress has affected industries of all kinds, including the fast-growing chemical industry. Chemical companies’ transitions toward more widespread usage of solar energy stands to not only provide economic benefits, but also improve the environmental status of the sector. Here’s how

More related information

-

Solomon Islands bifacial solar panel factory

Solomon Islands bifacial solar panel factory

-

New solar panel production plant

New solar panel production plant

-

Can 40w invest in a solar photovoltaic panel factory

Can 40w invest in a solar photovoltaic panel factory

-

New solar photovoltaic panel factory in West Africa

New solar photovoltaic panel factory in West Africa

-

Solar Panel Tile Factory

Solar Panel Tile Factory

-

Georgia solar panel processing plant

Georgia solar panel processing plant

-

Moroccan solar panel photovoltaic factory

Moroccan solar panel photovoltaic factory

-

Georgia has a photovoltaic solar panel factory

Georgia has a photovoltaic solar panel factory

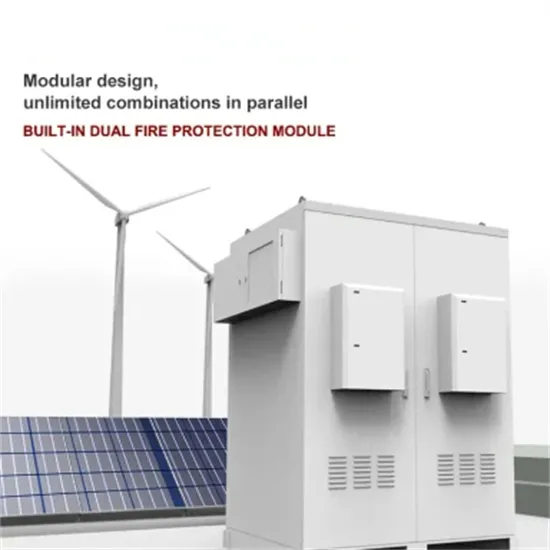

Commercial & Industrial Solar Storage Market Growth

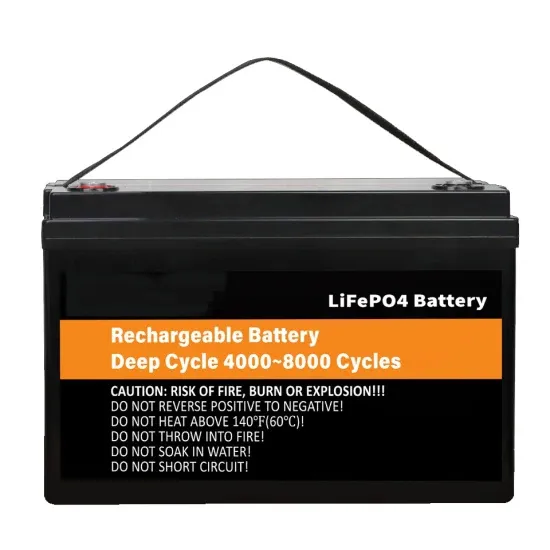

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.