Battery Cell Module Pack: Everything You Need to Know

While the terms "battery cell," "battery module," and "battery pack" are often used interchangeably, the battery cell module pack refers to different

Get Price

Mastering the Art of Lithium Battery Pack Assembly: A

Through our comprehensive guide, you will become a master of the art of lithium battery pack assembly, understanding the key points and best practices at each step.

Get Price

Battery Factory How to Build the Lithium-Ion Battery

Uncover the secrets of how lithium-ion battery pack processes and components are manufactured in lithium-ion battery factories.

Get Price

How to Build a 18650 Battery Pack,A Complete Guide

Learn how to build 18650 battery packs with step-by-step assembly, BMS integration, safety precautions, and procurement advice. Ideal

Get Price

Battery Cell, Module, or Pack: What''s the difference?

You''ll learn about the distinctions between battery cells, modules, and packs, as well as how to identify these essential elements for optimal battery management.

Get Price

Battery Pack Assembly: Techniques and Materials Used

Electric vehicles rely on lithium-ion batteries for energy storage, making the battery pack the heart of an EV. Its assembly involves intricate

Get Price

Battery Manufacturing Process: Materials, Production

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get Price

Complete Guide to Lithium Battery Pack Design and Assembly

A lithium battery pack is not just a simple assembly of batteries. It is a highly integrated and precise system project. It covers multiple steps, including cell selection,

Get Price

How Are Lithium Ion Batteries Manufactured

Discover the step-by-step process of lithium ion battery manufacturing, from raw material extraction to battery pack assembly,

Get Price

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

In this step-by-step guide, as a professional lithium battery pack manufacturer, I''ll walk you through the entire DIY battery pack assembly process to help you build a safe, high

Get Price

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

Cell format selection determines the fundamental characteristics of your battery pack design. The physical configuration of cells directly affects energy capacity, thermal

Get Price

Lithium Battery Pack Assembly: A Comprehensive Guide

We encase the battery pack in a robust structural housing to protect the delicate internal components and ensure safe operation. We

Get Price

Mastering the Art of Lithium Battery Pack Assembly: A

Through our comprehensive guide, you will become a master of the art of lithium battery pack assembly, understanding the key points and best

Get Price

What Is the Process of Lithium-Ion Battery Pack

The lithium battery pack plays a crucial role in the manufacture of lithium-ion batteries, involving packaging, encapsulation, and assembly. This

Get Price

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

Get Price

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

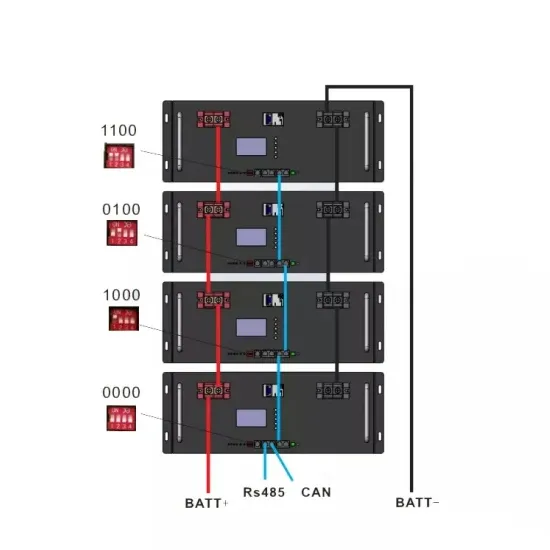

In order to deliver the required power and energy as per the application, it is necessary to assemble the individual Li-ion cells in series and parallel configuration to make up a Li-ion

Get Price

The Ultimate Guide For Lithium-Ion Battery Packs Components

Lithium-ion battery packs are complex assemblies that include cells, a battery management system (BMS), passive components, an enclosure, and a thermal management system.

Get Price

Battery Pack Assembly: Techniques and Materials Used

Electric vehicles rely on lithium-ion batteries for energy storage, making the battery pack the heart of an EV. Its assembly involves intricate processes to ensure reliability, energy

Get Price

How are Lithium-ion Battery Packs Manufactured?

The cell assembly process in lithium batteries involves arranging and connecting individual cells to form a complete battery pack. This includes cell sorting, mounting, resistance and laser

Get Price

Battery Pack Assembly: From Cells to Power Packs

Each battery pack can be tailored to specific needs by adjusting the number of batteries and modules it contains. This customization is a remarkable aspect of battery pack assembly, as it

Get Price

The Ultimate Guide For Lithium-Ion Battery Packs

Lithium-ion battery packs are complex assemblies that include cells, a battery management system (BMS), passive components, an enclosure, and a

Get Price

Mastering the Battery Pack Assembly Process: A

Conclusion The battery pack assembly process is a sophisticated and highly specialized field that underpins the success of modern energy

Get Price

Battery Pack Manufacturing Process: Step-by-Step

Learn the steps behind battery pack manufacturing, from cell assembly to BMS integration, ensuring reliable power for diverse applications.

Get Price

Lithium Battery Pack Assembly: A Comprehensive Guide

We encase the battery pack in a robust structural housing to protect the delicate internal components and ensure safe operation. We expertly integrate insulation materials and

Get Price

How Are Lithium Battery Packs Assembled?

By following the key steps involved in lithium battery pack assembly, including cell selection and testing, cell arrangement and connection, BMS integration, and final assembly and testing,

Get Price

Function and components of battery pack & BMS –

Introduction Lithium-ion battery packs for electric vehicles have large battery capacity, many series and parallel connections, complex systems, and high

Get Price

Complete Guide to Lithium Battery Pack Design and Assembly

What is a Lithium Battery Pack? A lithium battery pack is an integrated battery system. It is built by connecting many individual cells in series and parallel. It includes a

Get Price

Lithium Battery Pack Assembly: A Comprehensive Guide

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the

Get Price

More related information

-

What is the reasonable tensile strength of a pack lithium battery

What is the reasonable tensile strength of a pack lithium battery

-

What is the charging voltage of a 7 2v lithium battery pack

What is the charging voltage of a 7 2v lithium battery pack

-

Pack lithium battery automatic assembly price

Pack lithium battery automatic assembly price

-

What is the normal voltage of Angola lithium battery pack

What is the normal voltage of Angola lithium battery pack

-

Lithium battery assembly double pack

Lithium battery assembly double pack

-

Lithium battery pack assembly equipment

Lithium battery pack assembly equipment

-

What power source can replace lithium battery pack

What power source can replace lithium battery pack

-

Lithium battery pack design and assembly

Lithium battery pack design and assembly

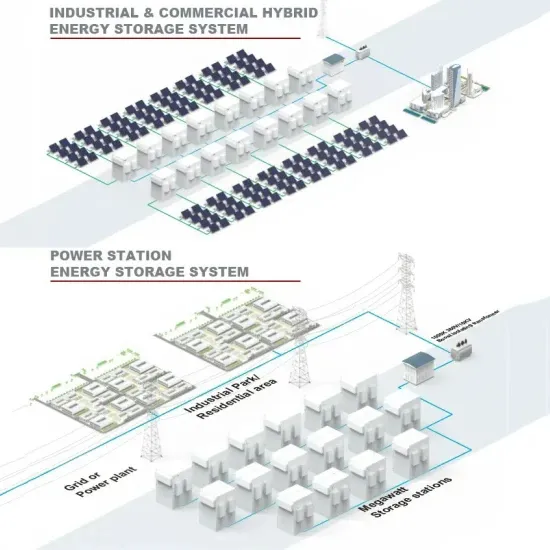

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.