Calculation of solar inverter efficiency

Inverters inherently experience power losses due to conversion, thermal effects, and parasitic components; understanding these losses can help maximize energy yield. Solar

Get Price

How to Reduce DC to AC Inverter Losses & Boost

Understanding inverter power loss, selecting efficient inverters and adopting appropriate energy saving measures to improve the efficiency of

Get Price

Solar inverters and clipping: What DC/AC inverter

The key driver here is the "clipping loss": when the DC power feeding an inverter is more than the inverter can handle, the resulting power is

Get Price

Efficiency of Inverter: Calculation & Equation Guide

The performance simulations can analyze the whole efficiency of inverter curve for devices with CEC test data, rather than using a fixed, weighted efficiency to determine DC/AC

Get Price

What DC to AC inverter load ratio is ideal for your

The DC to AC inverter ratio (also known as the Inverter Load Ratio, or "ILR") is an important parameter when designing a solar project.

Get Price

Do Inverters Lose Efficiency over Time?

The short answer is yes, inverters can lose efficiency over time, but the extent and speed at which this happens depend on various factors. All electronic components degrade

Get Price

Clipping: Pushing the DC-to-AC inverter clipping ratio to the limit

In a "regular" system (constrained by physical space or by budget), the DC/AC ratio is a tradeoff of clipping losses versus inverter cost. A smaller-capacity inverter will cost less up

Get Price

Efficiency of Inverter: Calculation & Equation Guide

The short answer is yes, inverters can lose efficiency over time, but the extent and speed at which this happens depend on various factors. All electronic components degrade

Get Price

Loss Minimization in Inverters calculation for Electrical Engineering

Calculation Example: The efficiency of an inverter is defined as the ratio of the AC output power to the DC input power. The higher the efficiency, the less power is lost in the

Get Price

What is Inverter Efficiency?

Inverter efficiency is a critical factor to consider when choosing an inverter for various applications, including solar power systems, electric vehicle chargers, uninterruptible

Get Price

Setting up losses

Learn to optimize your PV energy system by adjusting cabling, degradation, and environmental losses for improved efficiency and performance.

Get Price

Clipping: Pushing the DC-to-AC inverter clipping ratio

In a "regular" system (constrained by physical space or by budget), the DC/AC ratio is a tradeoff of clipping losses versus inverter cost. A smaller

Get Price

How much energy do you lose converting DC to AC?

If you look at the total energy lost due to using an inverter, then total losses are average 75% from using an inverter. This is due to modern appliances all running on DC power.

Get Price

LOSS COMPARISON OF TWO AND THREE-LEVEL

This paper investigates semiconductor and DC-link capacitor losses in two two-level and two three-level voltage source inverters. The components of the four inverters are selected to have

Get Price

Inverter Efficiency: Understanding Conversion Rates

Inverter manufacturers in India must focus on designing products with high-quality components and advanced control algorithms to improve

Get Price

Photovoltaic Inverter Reliability Assessment

The homegrown inverter, as explained in Chapter 1, is a two-stage inverter with a DC-DC boost converter followed by an H-bridge inverter. The thermal model is developed for all six switches

Get Price

How to Reduce DC to AC Inverter Losses & Boost Efficiency?

Understanding inverter power loss, selecting efficient inverters and adopting appropriate energy saving measures to improve the efficiency of home energy use.

Get Price

What percentage of losses occur in conversion from DC to AC?

Expected losses are in the 5-15% range, but many inverters are less efficient when operated at low power. While the panels may be capable of supplying a certain amount of

Get Price

10 Solar PV System Losses – How To Calculate Solar Panel

PV system losses have a substantial impact on the overall efficiency and output power of solar panel arrays. Good solar design takes into account 10 main PV losses, while best design and

Get Price

Loss Calculation in a Three-Phase 3-Level Inverter

This example shows how to compute switching losses in a three-phase 3-level inverter, combining Specialized Power Systems and Simscape™ blocks.

Get Price

Understanding PV System Losses, Part 4: Solar Panel Tilt, Solar

Looking to understand PV system losses in detail? Part 4 examines Environmental Conditions, Inverter Losses & Clipping, and more.

Get Price

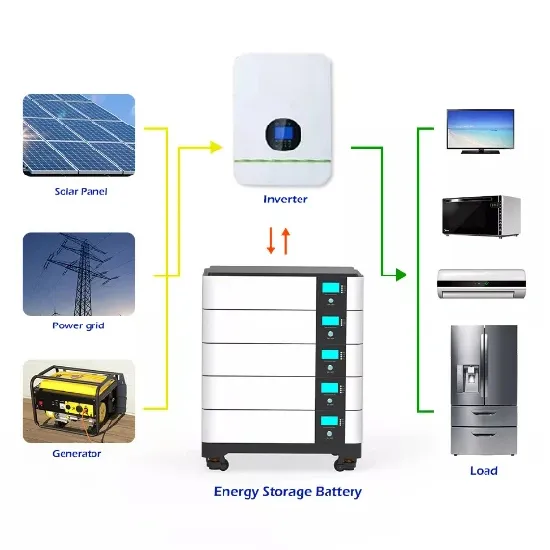

DC to AC Power Conversion Explained: Your Guide to Inverters

Note: High-quality inverters with MPPT technology can significantly improve the performance of renewable energy systems, reducing energy losses and increasing overall efficiency. The Role

Get Price

How much energy do you lose converting DC to AC?

DC-based lighting (LED) is as much as 75% more efficient than incandescent lighting. How does the conversion from DC to AC occur? The energy loss from DC to AC

Get Price

A Look at Inverter Inefficiencies

Many 120V devices can run on DC without using an inverter and the AC/DC wall-wort. You can simply read the output specs of the wall-wort or the input specs of the device, to determine if it

Get Price

A Look at Inverter Inefficiencies

Many 120V devices can run on DC without using an inverter and the AC/DC wall-wort. You can simply read the output specs of the wall-wort or the input specs

Get Price

Help me understand power losses going from DC to AC?

The relationship between array size (DC) and inverter size (AC) is known as DC:AC ratio. Historically, 1.2 ~ 1.3 is a considered good ratio to minimize clipping (losses)

Get Price

Understanding DC/AC Ratio

Thus a 9 kW PV array paired with a 7.6 kW AC inverter would have an ideal DC/AC ratio with minimal power loss. Clipping Losses and DC/AC Ratio When

Get Price

6 FAQs about [DC inverter losses]

How much power does a solar inverter lose?

Expected losses are in the 5-15% range, but many inverters are less efficient when operated at low power. While the panels may be capable of supplying a certain amount of power, this doesn't matter until there is sufficient load to consume that power.

How do inverter losses affect a design?

The process of selecting the topology, components and operating parameters (voltage, current and switching frequency) of an inverter is highly affected by the anticipated inverter losses. An accurate estimate of the losses occurring in each part of an inverter can significantly contribute to achieving an enhanced inverter design.

What if inverter load is less than 15%?

In general, if the inverter is loaded less than 15%, the efficiency will be low. As a result, a good match between inverter capacity and load capacity will allow us to obtain more efficiency, which is more ac output power from the inverter for the same DC input power. Efficiency of Inverter per Output Power (Reference: inverter.com)

Do two-level inverters have switching losses?

Losses in two-level inverters have been reported extensively in the literature. Researchers have also investigated semiconductor losses in three-level inverters. Estimates of switching losses have been obtained using approximations of IGBT and diode I-V switching characteristics [1, 4, 17, 18].

How efficient is a power inverter?

By efficiency, we mean how much of the electricity that passes into the inverter is converted into usable AC (nothing is ever 100 percent efficient, there will always be some losses in the system). This efficiency figure will fluctuate depending on how much power is being used at the time, with greater power resulting in higher efficiency.

How well do you know inverter clipping losses?

We’ve previously shown that over-power clipping losses aren’t nearly what most people expect them to be—for a DC-to-AC ratio of 1.2 in Georgia, an engineer can expect clipping losses of just 0.2%.

More related information

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.

US DC inverter device

US DC inverter device

Inverter DC high voltage protection

Inverter DC high voltage protection

The inverter voltage doubler output is DC

The inverter voltage doubler output is DC

Series DC Motor Inverter

Series DC Motor Inverter

Inverter DC pump voltage

Inverter DC pump voltage

Afghanistan DC Inverter Device Factory

Afghanistan DC Inverter Device Factory

Ultra-high current DC special inverter

Ultra-high current DC special inverter

Industrial inverter DC to AC

Industrial inverter DC to AC